How to Navigate the Komatsu PC200 Parts Manual for Efficient Repairs

In the realm of heavy machinery, understanding every component of your equipment is paramount. This is where a detailed parts manual comes into play. The Komatsu PC200 is a renowned name in the industry, known for its durability, efficiency, and top-notch performance. But, like any other machinery, it requires regular maintenance and occasional part replacements. This is where the Komatsu PC200 parts manual becomes an invaluable resource.

The Komatsu PC200 is not just a piece of equipment; it’s an investment. Owners and operators have trusted this machinery for various construction and excavation tasks, making it a staple in many job sites. The parts manual for this equipment is more than just a list of components. It’s a comprehensive guide that provides insights into the machine’s anatomy, ensuring that users can address maintenance needs effectively.

Having a Komatsu PC200 parts manual is akin to having a detailed map of your machinery. It not only lists the parts but also provides crucial information about each component’s function, location, and maintenance requirements. This ensures that operators and technicians can quickly identify and replace worn-out or damaged parts, ensuring the machine’s longevity and optimal performance.

Understanding the Layout of the Komatsu PC200 Parts Manual

The Komatsu PC200 parts manual is meticulously designed to provide users with a clear and comprehensive understanding of the machine’s components. Its layout is structured to ensure that even those unfamiliar with such manuals can navigate it with ease and find the information they need. Let’s delve into the manual’s structure and the common symbols and notations used.

Overview of the Manual’s Structure:

- Table of Contents: Positioned at the beginning, this section provides a quick overview of the manual’s layout. It lists all the chapters or sections, making it easier for users to jump to specific parts or topics.

- General Information: This section provides an introduction to the Komatsu PC200 and its general specifications. It might include details about the machine’s weight, dimensions, and basic operational guidelines.

- Detailed Parts Breakdown: Organized systematically, this section lists all the parts of the Komatsu PC200. It’s further divided into subsections based on the machine’s major assemblies or systems, such as the hydraulic system, engine components, undercarriage, and more.

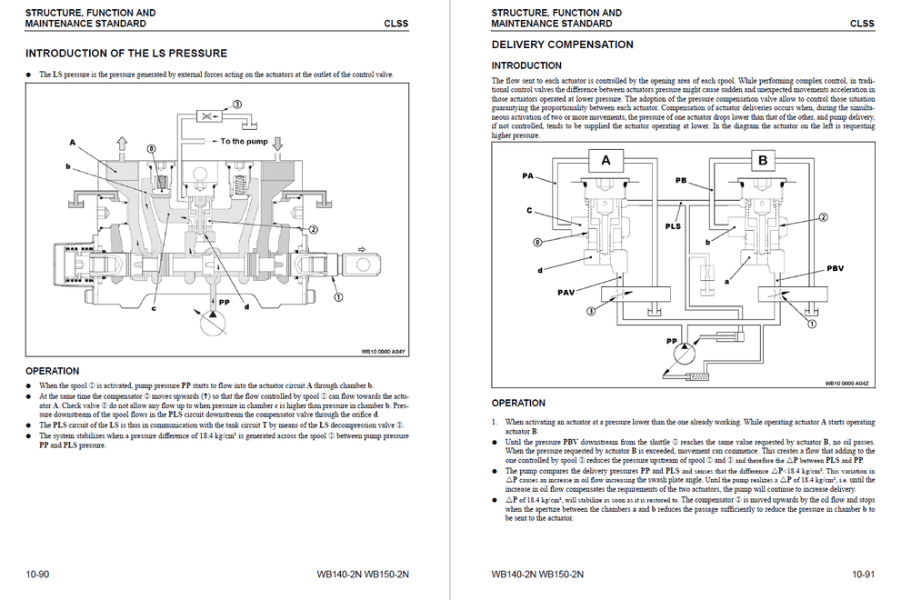

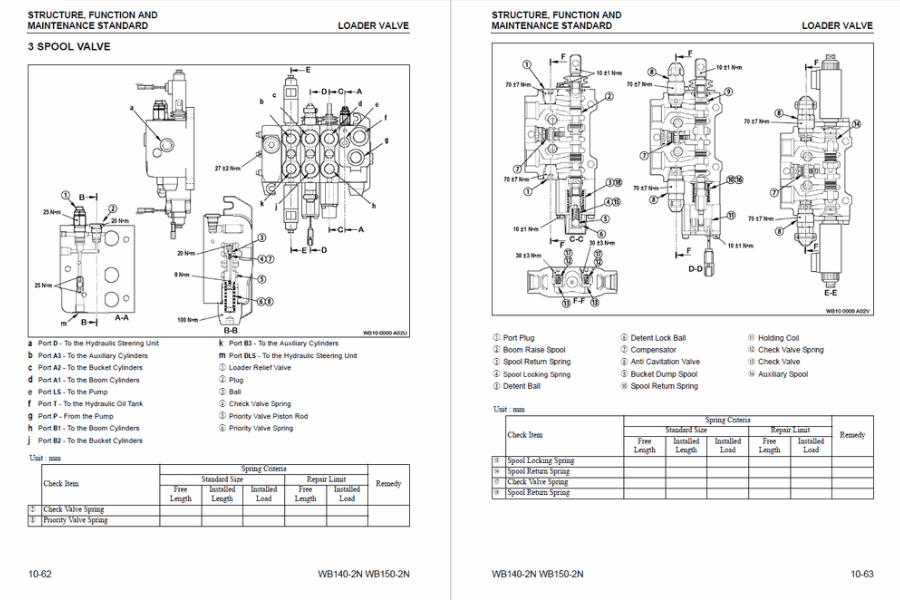

- Illustrations and Diagrams: Accompanying the parts list are high-resolution illustrations and diagrams. These visuals provide a clear picture of each part, its location, and how it fits within the larger assembly.

- Part Numbers and Descriptions: Every component listed in the manual comes with a unique part number and a brief description. This ensures that users can order the correct replacement parts when needed.

- Maintenance and Troubleshooting: Some manuals include a section dedicated to maintenance tips, troubleshooting guides, and best practices to keep the machine in optimal condition.

Common Symbols and Notations Used:

- Arrow Symbols: Often used in diagrams to indicate the flow of fluids or the direction of movement.

- Circled Numbers: These are typically used to reference specific parts in an illustration. The circled number in the diagram corresponds to a numbered list that provides the part’s name and number.

- Warning and Caution Symbols: These symbols alert users to potential hazards or important information regarding the installation or replacement of parts.

- Zoomed-in or Detailed Views: Some complex parts might have a zoomed-in view or a separate detailed diagram to provide a clearer understanding.

- Abbreviations: The manual may use abbreviations for common terms. For instance, “Hyd.” might be used for “Hydraulic.” A list of these abbreviations is usually provided at the beginning of the manual.

The Komatsu PC200 parts manual is a well-organized document, designed to be user-friendly. Familiarizing oneself with its layout and the common symbols used can significantly streamline the maintenance and repair process. Whether you’re a seasoned technician or a new operator, understanding the manual’s structure is the first step in harnessing its full potential.

komatsu pc200 parts manual

Locating Specific Parts and Their Details

Navigating through a detailed parts manual, especially for a machine as intricate as the Komatsu PC200, can initially seem daunting. However, with a systematic approach and a clear understanding of the manual’s layout, locating specific parts and their details becomes a straightforward task. Here’s a guide to help you use the Komatsu PC200 parts manual effectively:

Using the Index and Table of Contents Effectively:

- Start with the Table of Contents: Located at the beginning of the manual, the table of contents provides a bird’s-eye view of the manual’s structure. It lists all the major sections and subsections, allowing users to quickly identify the section they need.

- Refer to the Index: Typically found at the end of the manual, the index is an alphabetical list of parts, assemblies, and topics covered in the manual. If you know the name or a keyword related to the part you’re looking for, the index will guide you to the exact page number.

- Utilize Chapter or Section Headers: As you navigate through the manual, each section or chapter will have a clear header, often accompanied by a brief description. This can help you quickly ascertain if you’re in the right section.

Tips for Quickly Finding Specific Parts or Assemblies:

- Use the Search Function: If you’re using a digital version of the Komatsu PC200 parts manual, leverage the search function. Simply input the part name or number, and the software will highlight all instances within the manual.

- Bookmark Frequently Accessed Pages: Whether you’re using a physical or digital manual, marking or bookmarking pages you frequently refer to can save time in future searches.

- Familiarize Yourself with Major Assemblies: The manual is often organized by major assemblies or systems, such as the engine, hydraulic system, or transmission. If you know which assembly your part belongs to, you can jump directly to that section.

- Leverage Illustrations and Diagrams: Visual aids are invaluable when locating parts. Once you’re in the right section, scan the diagrams to find the visual representation of the part. These illustrations are usually labeled with part numbers or references that you can cross-reference with the parts list.

- Note the Page Layout: Most manuals maintain a consistent layout, with illustrations on one side and the corresponding parts list on the opposite page. Familiarizing yourself with this layout can expedite your search.

- Seek Assistance: If you’re struggling to locate a part, don’t hesitate to ask a colleague or contact the manufacturer’s support. Sometimes, a second pair of eyes or expert guidance can quickly resolve your query.

The Komatsu PC200 parts manual is a treasure trove of information, meticulously organized to assist users in their maintenance and repair endeavors. By mastering the art of navigating this manual, technicians and operators can ensure that they’re always equipped with the right knowledge to keep their machinery in top-notch condition.

Efficient Troubleshooting with the Manual

Troubleshooting machinery issues can be a complex task, especially when dealing with intricate equipment like the Komatsu PC200. However, with the Komatsu PC200 parts manual at your disposal, the process becomes significantly more manageable. The manual is designed not only to list parts but also to assist operators and technicians in diagnosing and resolving common problems. Here’s how you can leverage the manual for efficient troubleshooting:

Using the Manual’s Diagrams and Schematics for Problem-Solving:

- Understand the Symbols: Before diving into the diagrams, familiarize yourself with the symbols used. These symbols represent various components, connections, and flow directions. A legend or key is often provided to explain these symbols.

- Follow the Flow: Many issues, especially in hydraulic or electrical systems, can be traced by following the flow or circuit diagrams. Start at the source and trace the path, looking for discrepancies or potential blockages.

- Zoom into Detailed Views: For complex assemblies, the manual often provides zoomed-in or exploded views. These detailed diagrams can help you understand how individual parts fit together and identify any misalignments or missing components.

- Cross-Reference with Part Descriptions: Once you’ve identified a potential issue in the diagram, cross-reference it with the part description. This will provide additional details about the component’s function, specifications, and potential failure modes.

Identifying Common Issues and Their Potential Solutions in the Manual:

- Check the Troubleshooting Section: Many parts manuals, including the Komatsu PC200 parts manual, include a dedicated troubleshooting section. This section lists common issues, their symptoms, potential causes, and recommended solutions.

- Look for Wear Indicators: Some parts are designed with wear indicators or benchmarks that signal when replacement is needed. The manual will detail these indicators and explain how to interpret them.

- Refer to Maintenance Intervals: Regular maintenance is crucial to prevent issues. The manual will provide recommended maintenance intervals for various components. If you’re facing a problem, check if the affected part is due for maintenance or replacement.

- Seek Expert Opinions: If you’re unable to diagnose an issue using the manual, consider reaching out to experts or the manufacturer’s support team. They might provide insights or direct you to specific sections of the manual that address your concern.

- Stay Updated: Manufacturers occasionally release updates or revisions to their manuals, incorporating feedback from the field and addressing new issues. Ensure you have the latest version of the Komatsu PC200 parts manual for the most accurate troubleshooting guidance.

The Komatsu PC200 parts manual is an invaluable tool for troubleshooting. With its detailed diagrams, comprehensive part descriptions, and dedicated troubleshooting sections, it equips operators and technicians with the knowledge they need to diagnose and resolve issues efficiently. By understanding how to navigate and utilize the manual effectively, you can ensure that your machinery remains in optimal condition, minimizing downtime and maximizing productivity.

komatsu pc200 parts manual

Ordering Replacement Parts

Ordering replacement parts for machinery, especially for a sophisticated machine like the Komatsu PC200, requires precision and attention to detail. Using the wrong part can lead to inefficiencies, increased wear and tear, or even catastrophic failures. The Komatsu PC200 parts manual is an essential tool in this process, ensuring that you order the right components every time. Here’s a guide to help you order replacement parts with confidence:

How to Determine the Correct Part Numbers:

- Locate the Affected Assembly in the Manual: Start by identifying the broader system or assembly where the part is located. For instance, if you’re looking for a hydraulic pump seal, navigate to the hydraulic system section.

- Use the Diagrams: Once in the correct section, refer to the detailed diagrams and illustrations. These visuals will show each part in its relative position, helping you identify the exact component you need.

- Cross-Reference with the Parts List: Adjacent to or near the diagrams, you’ll find a parts list. This list will have a description of each part, its unique part number, and sometimes additional specifications. Once you’ve identified the part in the diagram, cross-reference its label or number with the parts list to find the correct part number.

- Check for Variants: Some parts might have multiple variants based on the machine’s serial number, model variations, or manufacturing date. Ensure you’re selecting the part number that matches your specific Komatsu PC200 variant.

Tips for Ensuring You Order the Correct Components:

- Double-Check Part Numbers: Before placing an order, double-check the part numbers against the manual. A simple transposition of numbers or a minor error can lead to ordering the wrong component.

- Use the Manual’s Glossary or Index: If you’re unsure about a part’s name or description, the manual’s glossary or index can help. These sections provide definitions and can guide you to the correct page or section.

- Consult with Authorized Dealers: When in doubt, consult with an authorized Komatsu dealer or service center. They have expertise in parts identification and can confirm if you’ve selected the right component.

- Keep a Record: Maintain a log of all the parts you order, including part numbers, descriptions, and the date of order. This record can be invaluable for future maintenance or repairs.

- Consider Using Digital Manuals: If you’re using a digital version of the Komatsu PC200 parts manual, utilize the search function. Inputting keywords or partial part numbers can quickly lead you to the right section.

- Beware of Counterfeit Parts: Always order from reputable sources. While third-party or aftermarket parts might be cheaper, they may not meet Komatsu’s quality standards. Using genuine parts ensures compatibility, performance, and longevity.

The Komatsu PC200 parts manual is a crucial resource when ordering replacement parts. By understanding how to navigate the manual and cross-reference diagrams with part lists, you can ensure that you always order the correct components. This precision not only saves time and money but also guarantees the optimal performance and safety of your machinery.

Maintenance Tips and Best Practices

Regular maintenance is the cornerstone of ensuring the longevity and optimal performance of heavy machinery like the Komatsu PC200. The Komatsu PC200 parts manual serves as a comprehensive guide, providing insights into the machine’s components and offering best practices for maintenance. Here are some maintenance tips and recommendations derived from the manual:

Using the Manual for Regular Maintenance:

- Scheduled Maintenance Intervals: The manual typically provides a maintenance schedule, detailing the intervals at which specific parts should be inspected, serviced, or replaced. Adhering to this schedule ensures that the machine operates efficiently and reduces the risk of unexpected breakdowns.

- Detailed Procedures: For each maintenance task, the manual provides step-by-step procedures, often accompanied by diagrams or illustrations. Following these procedures ensures that maintenance is carried out correctly and safely.

- Lubrication Guide: Proper lubrication is vital for the smooth operation of machinery. The manual will specify the type of lubricant to use, the points of application, and the frequency of lubrication.

- Safety Precautions: Before undertaking any maintenance task, consult the manual for safety precautions. This might include disengaging power, using protective gear, or ensuring the machine is on stable ground.

Recommendations for Prolonging the Lifespan of the Komatsu PC200:

- Use Genuine Parts: When replacing parts, always opt for genuine Komatsu components. These parts are designed to the machine’s exact specifications, ensuring compatibility and performance.

- Regular Inspections: Even if the machine seems to be operating smoothly, conduct regular visual and auditory inspections. Early detection of wear, leaks, or unusual noises can prevent more significant issues down the line.

- Cleanliness is Key: Dirt, debris, and contaminants can accelerate wear and lead to malfunctions. Regularly clean the machine, paying special attention to filters, vents, and exposed moving parts.

- Protect from Extreme Conditions: If possible, store the Komatsu PC200 in a sheltered location, protected from extreme weather conditions. Prolonged exposure to rain, sun, or freezing temperatures can adversely affect the machine’s components.

- Train Operators: Ensure that all operators are adequately trained, not just in operating the machine but also in basic maintenance and troubleshooting. An informed operator is more likely to detect issues early and operate the machine in a manner that reduces wear.

- Maintain Records: Keep a detailed log of all maintenance activities, including dates, parts replaced, and any issues detected. This record can be invaluable for future maintenance planning and for diagnosing recurring issues.

- Stay Updated: Manufacturers occasionally release updates, bulletins, or revised manuals. Stay informed about these updates, as they might contain crucial information about emerging issues or improved maintenance practices.

The Komatsu PC200 parts manual is more than just a list of components. It’s a comprehensive guide to maintaining the machine, ensuring its longevity, and optimizing its performance. By following the manual’s recommendations and complementing them with best practices, you can ensure that your Komatsu PC200 remains a reliable workhorse for years to come.

komatsu pc200 parts manual

Digital vs. Physical Manuals: Pros and Cons

In today’s digital age, many companies offer both digital and physical versions of their product manuals. Each format has its own set of advantages and drawbacks. For machinery as intricate as the Komatsu PC200, having a comprehensive parts manual is crucial. Let’s delve into the pros and cons of both digital and physical manuals, helping you decide which might be best suited for your needs.

Digital Manuals:

Pros:

- Search Functionality: Digital manuals often come in PDF or other searchable formats. This allows users to quickly search for specific terms, part numbers, or sections, streamlining the process of finding information.

- Portability: Digital manuals can be stored on a variety of devices, including smartphones, tablets, and laptops. This means you can access the manual from anywhere, whether you’re in the office or out in the field.

- Interactive Features: Some digital manuals come with interactive features, such as hyperlinks, embedded videos, or 3D models, enhancing the user experience and providing more in-depth information.

- Easy Updates: Manufacturers can easily update digital manuals to include new information, corrections, or enhancements. Users can then download the latest version, ensuring they always have up-to-date information.

Cons:

- Dependency on Devices: To access a digital manual, you need a functioning device with sufficient battery life. In remote locations or during long working hours, this can be a limitation.

- Potential for Technical Issues: Digital files can become corrupted, or devices can malfunction, making the manual inaccessible.

- Learning Curve: For those less familiar with digital technology, navigating a digital manual might pose a challenge.

Physical Manuals:

Pros:

- Tactile Experience: Many people find the tactile experience of flipping through physical pages more intuitive and satisfying. It can also be easier to bookmark or highlight important sections.

- No Device Dependency: A physical manual doesn’t require any device or power source. It’s always accessible, regardless of where you are or the conditions you’re working under.

- Durability: Physical manuals, especially those designed for industrial use, are often printed on durable paper and bound to withstand wear and tear.

Cons:

- Bulk and Weight: Physical manuals can be bulky and heavy, making them less convenient to carry around, especially if you’re on the move.

- Wear and Tear: Over time, physical manuals can become worn out, pages can get torn, and information can become illegible.

- Updates: Unlike digital versions, physical manuals can’t be easily updated. If there are changes or corrections, you might need to order a new edition.

Both digital and physical Komatsu PC200 parts manuals have their merits. The best choice often depends on personal preference and the specific circumstances under which you’ll be using the manual. Some professionals prefer to keep both versions on hand: a digital copy for quick searches and portability, and a physical copy as a reliable backup and for more in-depth study. Whatever your choice, ensure that the manual is always accessible, as it’s an invaluable resource for maintaining and troubleshooting the Komatsu PC200.

komatsu pc200 parts manual

Common Mistakes to Avoid When Using the Manual

While the Komatsu PC200 parts manual is a valuable resource, it’s essential to use it effectively and avoid common mistakes that can lead to errors in maintenance, troubleshooting, or ordering replacement parts. Here are some common pitfalls to steer clear of:

1. Overlooking Key Details:

Mistake: Rushing through the manual or assuming you already know the machine inside out can lead to missing critical information.

Prevention:

- Take your time: Thoroughly review each section of the manual, paying attention to details.

- Follow the prescribed maintenance schedule and procedures without shortcuts.

- Don’t skip safety warnings or precautions. Neglecting safety can lead to accidents or equipment damage.

2. Misinterpreting Diagrams or Part Descriptions:

Mistake: Misinterpreting diagrams or part descriptions can result in incorrectly identifying components or their functions.

Prevention:

- Study the legends and symbols used in diagrams and schematics. The manual often provides a legend explaining the meaning of symbols.

- Cross-reference part descriptions with the diagrams. Ensure that the part you’re looking for matches the description and location in the diagram.

- Seek clarification from the manufacturer or authorized dealers if you’re uncertain about a part’s identification or function.

3. Neglecting to Update the Manual:

Mistake: Using an outdated version of the manual can lead to incorrect information or missing details, especially if there have been revisions or updates.

Prevention:

- Check for updates or revised editions of the manual from the manufacturer’s website or official sources.

- Ensure that all team members working with the manual have access to the latest version.

- Maintain a record of the manual’s revision history to track changes and updates.

4. Failing to Document Maintenance Activities:

Mistake: Neglecting to document maintenance activities can lead to confusion, duplication of efforts, or missed tasks.

Prevention:

- Keep a detailed log of all maintenance activities, including dates, parts replaced, and the reasons for replacement.

- Record any issues or anomalies observed during maintenance, even if they seem minor. Small issues can escalate if left unaddressed.

- Use a standardized format for documentation to ensure consistency.

5. Ordering Incorrect Parts:

Mistake: Ordering the wrong replacement parts can result in delays, downtime, and additional costs.

Prevention:

- Carefully cross-reference the part number in the manual with the manufacturer’s catalog or official supplier’s website before placing an

The Komatsu PC200 parts manual is not just a document; it’s your key to unlocking the full potential of your heavy machinery. Throughout this discussion, we’ve emphasized the vital role that this manual plays in the maintenance, troubleshooting, and efficient operation of the Komatsu PC200. It’s more than just a list of parts; it’s a comprehensive guide that empowers operators and technicians to keep this powerful machine in peak condition.

Understanding the Komatsu PC200 parts manual is not a one-time task but a continuous journey of learning and improvement. By thoroughly grasping the manual’s contents, you equip yourself with the knowledge needed to ensure the longevity and optimal performance of your machine. This, in turn, translates to reduced downtime, lower maintenance costs, and increased productivity.

We encourage you to embrace the manual as your trusted companion in the field. Avoid common mistakes, such as overlooking key details or misinterpreting diagrams, by taking the time to study and reference the manual regularly. Whether you choose the convenience of a digital version or the tactile feel of a physical manual, make it an integral part of your equipment management strategy.

Continuous learning is the key to efficient repairs and safe operations. As technology evolves and machinery becomes more sophisticated, staying up-to-date with the latest information in the manual is essential. Manufacturers may release updates or revisions, and new best practices may emerge. By keeping pace with these changes, you’ll remain at the forefront of machinery maintenance and ensure that your Komatsu PC200 continues to excel in its performance.

The Komatsu PC200 parts manual is not just a tool; it’s your guide to excellence in heavy machinery operation and maintenance. Embrace it, study it, and make it an integral part of your professional journey with the Komatsu PC200. Your commitment to understanding and utilizing this manual will not only benefit your own operations but also contribute to the overall efficiency and safety of the industry.